-40%

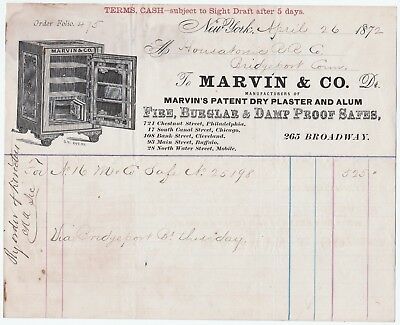

RARE Billhead Marvin Safe Co - New York NY - 1872 for Housatonic Railroad Co RR

$ 102.96

- Description

- Size Guide

Description

RARE Original Advertising BillheadMarvin Safe Company

Sold Large safe to Housatonic Railroad Company

New York, NY

1

872

For offer, a very nice old Advertising engraved / lithograph letter head / bill head! Fresh from an old prominent estate. Never offered on the market until now.

Vintage, Old, Original -

NOT

a Reproduction - Guaranteed !!

Nice graphic print showing safe - signed at bottom by engraver / artist J.W. Orr, NY . Marvin - manufacturers of Marvin's patent dry plaster and alum, Fire, burglar & damp proof safes. I believe this company later became the

Herring-Hall Marvin Co.

Sold safe to Housatonic RR Co., Bridgeport, CT.

In good to very good condition. Small paper remain on back, fold marks. Please see photos and scans for all details and condition.

NOTE : will be sent folded up as it was found unless otherwise specified.

If you collect 19th century Americana advertisement ad history, United States of America printing, locks, hardware, American business, industry, etc. this is a nice one for your paper or ephemera collection. Genealogy research importance as well. Combine shipping on multiple bid wins! 1758

A safe (also called a strongbox or coffer) is a secure lockable box used for securing valuable objects against theft and/or damage from fire. A safe is usually a hollow cuboid or cylinder, with one face being removable or hinged to form a door. The body and door may be cast from metal (such as steel) or formed out of plastic through blow molding. Bank teller safes typically are secured to the counter, have a slit opening for dropping valuables into the safe without opening it, and a time-delay combination lock to foil robbers/and or thieves. One significant distinction between types of safes is whether the safe is secured to a wall or structure or if it can be moved around. A less secure version (only suitable for petty cash) is usually called a cash-box.

History

The Chubb Building, Fryer Street, in Wolverhampton

[icon]

This section needs expansion. You can help by adding to it. (January 2012)

In 1835, English inventors Charles and Jeremiah Chubb in Wolverhampton, England, received a patent for a burglar-resisting safe and began a production of safes.[1] The Chubb brothers had produced locks since 1818. Chubb Locks was an independent company until 2000 when it was sold to Assa Abloy.

On November 2, 1886, inventor Henry Brown patented a "receptacle for storing and preserving papers." The container was fire retardant and accident resistant as it was made from forged metal. The box was able to be safely secured with a lock and key and also able to maintain organization by offering different slots to organize important papers.[2][3]

Specifications

Specifications for safes include some or all of the following parameters:

Burglar-resistance

Fire-resistance

Environmental resistance (e.g., to water or dust)

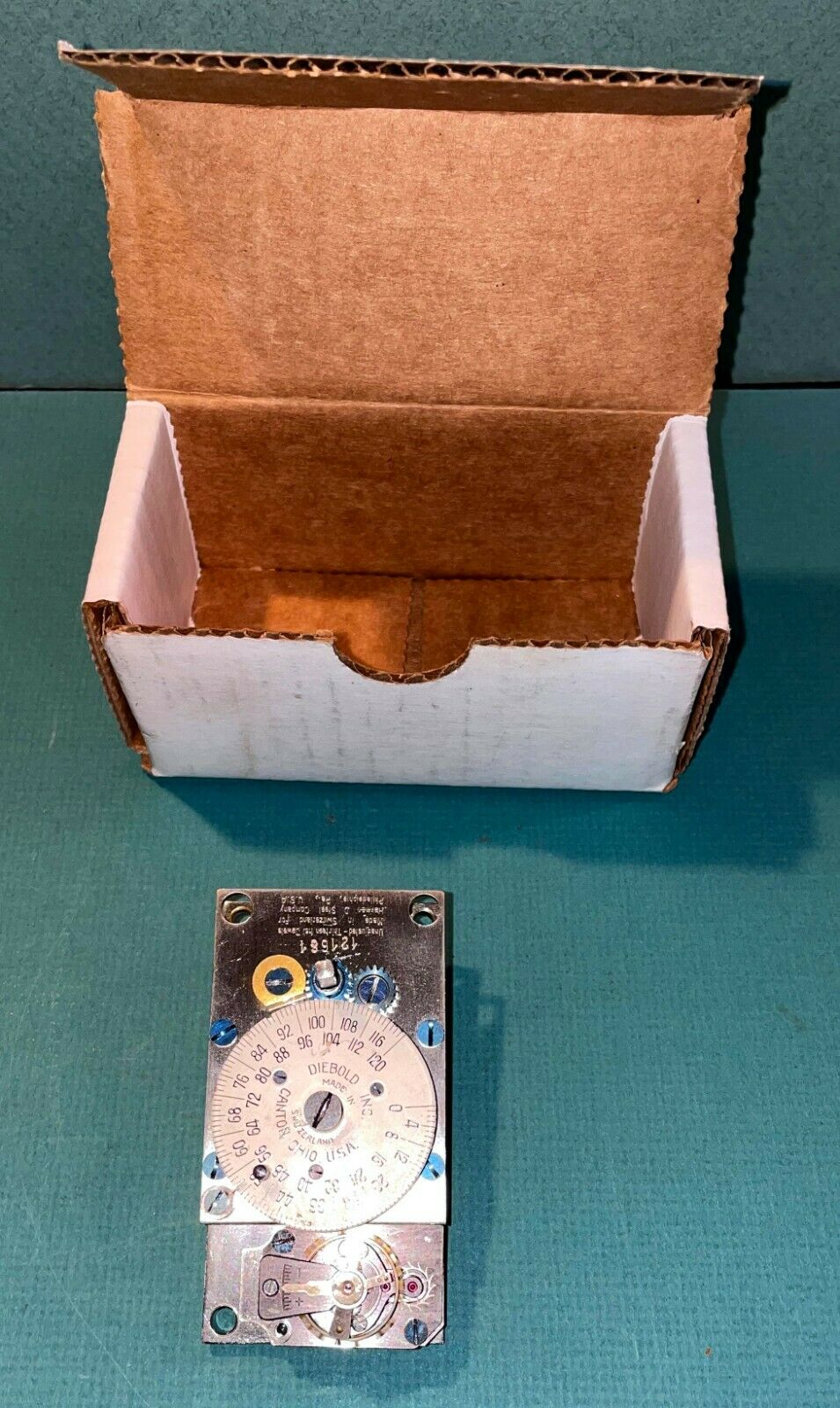

Type of lock (e.g., combination, key, time lock, electronic locking)

Location (e.g., wall safe, floor safe)

Smart safes as part of an automated cash handling system

It is often possible to open a safe without access to the key or knowledge of the combination; this activity is known as safe-cracking and is a popular theme in heist films.

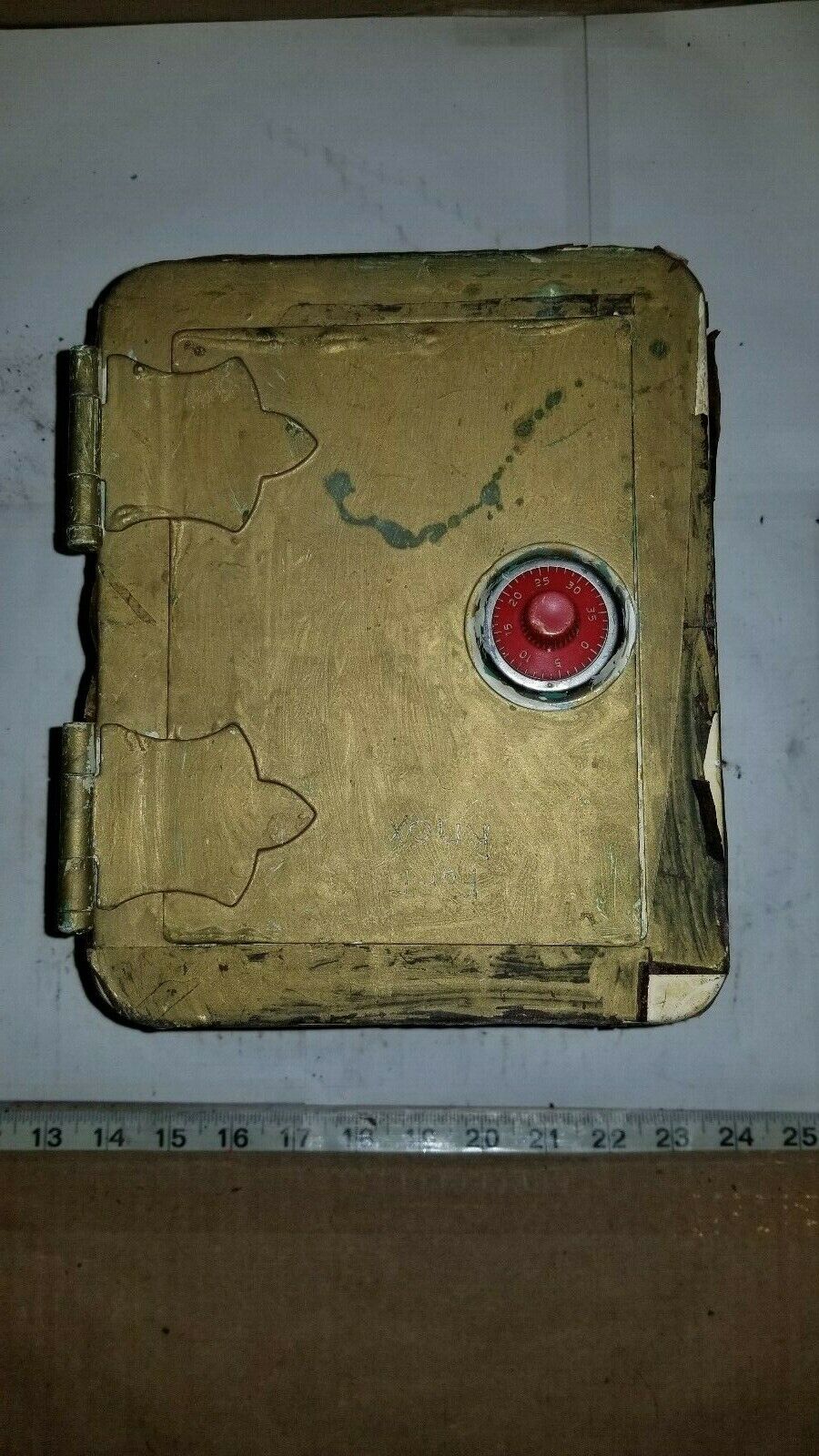

A diversion safe, or hidden safe, is a safe that is made from an otherwise ordinary object such as a book, a candle, a can, or even a wall outlet plug. Valuables are placed in these hidden safes, which are themselves placed inconspicuously (for example, a book would be placed on a book shelf).

Strongbox multiple locking mechanism

Fire resistant record protection equipment consists of self-contained devices that incorporate insulated bodies, doors, drawers or lids, or non-rated multi-drawer devices housing individually rated containers that contain one or more inner compartments for storage of records. These devices are intended to provide protection to one or more types of records as evidenced by the assigned Class rating or ratings; Class 350 for paper, Class 150 for microfilm, microfiche other and photographic film and Class 125 for magnetic media and hard drives.

These types of enclosures can be rated for periods of ½, 1, 2 and 4 hour durations.

In addition, these enclosures may be rated for their impact resistance, should the safe fall a number of feet to a lower level or have debris fall upon it during a fire.[4]

Burglary resistant safes are rated as to their resistance to the type of tools to be used in their attack and also the duration of the attack.

The attack durations are for periods of 15 min., 30 min. and 60 min.

Safes can also contain hardware that automatically dispenses cash or validates bills as part of an automated cash handling system.

Room-sized fireproof vaults

See also: Bank vault

For larger volumes of heat-sensitive materials, a modular room-sized vault is much more economical than purchasing and storing many fire rated safes. Typically these room-sized vaults are utilized by corporations, government agencies and off-site storage service firms. Fireproof vaults are rated up to Class 125-4 Hour for large data storage applications. These vaults utilize ceramic fiber, a high temperature industrial insulating material, as the core of their modular panel system. All components of the vault, not just the walls and roof panels, must be Class 125 rated to achieve that overall rating for the vault. This includes the door assembly (a double door is needed since there is no single Class 125 vault door available), cable penetrations, coolant line penetrations (for split HVAC systems), and air duct penetrations.

There are also Class 150 applications (such as microfilm) and Class 350 vaults for protecting valuable paper documents. Like the data-rated (Class 125) structures, these vault systems employ ceramic fiber insulation and components rated to meet or exceed the required level of protection.

In recent years room-sized Class 125 vaults have been installed to protect entire data centers. As data storage technologies migrate from tape-based storage methods to hard drives, this trend is likely to continue.

Fire-resistant safes

A reinforced, fireproof cabinet for dangerous chemicals.

A fire-resistant safe is a type of safe that is designed to protect its contents from high temperatures or actual fire. Fire resistant safes are usually rated by the amount of time they can withstand the extreme temperatures a fire produces, while not exceeding a set internal temperature, e.g., less than 350 °F (177 °C). Models are typically available between half-hour and four-hour durations.

In the UK the BS EN-1047 standard is set aside for data and document safes to determine their ability to withstand prolonged intense heat and impact damage.

Document safes are designed to maintain an internal temperature no greater than 177 °C (351 °F) while in a constantly heated environment in excess of 1,000 °C (1,830 °F).

Data safes are designed to maintain an internal temperature no greater than 55 °C (131 °F) while in a constantly heated environment in excess of 1,000 °C (1,830 °F).

These conditions are maintained for the duration of the test. This is usually at least 30 minutes but can extend to many hours depending on grade. Both kinds of safe are also tested for impact by dropping from a set height onto a solid surface and then tested for fire survivability once again.[5]

In the USA, both the writing of standards for fire-resistance and the actual testing of safes is performed by Underwriters Laboratories.

An in-floor safe installed in a concrete floor is very resistant to fire. However, not all floor safes are watertight and will often fill with water from fire hoses, therefore everything stored inside should be placed in either double zip lock bags, dry bags, or sealed plastic containers.

Reinforced, fireproof cabinets are also used for dangerous chemicals or flammable goods.

Wall safes

Wall safes are designed to provide hidden protection for documents and miscellaneous valuables. Adjustable depth allows the maximization of usable space when installed in different wall thicknesses. Some wall safes feature pry resistant recessed doors with concealed hinges for anti-theft protection. A painting can be hung over a wall safe to obscure it from public view.

Jewelry safes

Jewelry safes are burglary and fire safes made specifically to house jewelry and valuables. These high end safes are typically manufactured with interior jewelry chests of fine woods and fabric liners with a range of organizational configurations.

Safe-cracking

Main article: Safe-cracking

Safe cracking is opening a safe without a combination or key. There are many methods to safe cracking ranging from brute force methods to guessing the combination. The easiest method that can be used on many safes is "safe bouncing", which involves hitting the safe on top; this may cause the locking pin to budge, opening the safe.

UL certification for safes

Underwriters Laboratories (UL) testing certifications for safes are known to be some of the most rigorous and most respected in the world.[citation needed] They are only matched by B.T.U/VDMA certifications (Germany).[citation needed]

J.I.S. (Japan) and CSTB (France) preheat the oven with the safe inside until the temperature reaches the desired setting (as opposed to a sustained temperature of the rating), then the safe is cooled artificially (as opposed to naturally).[citation needed] Also, J.I.S. and CSTB only drop their safes from 13–15 feet (as opposed to 30). Rarely are safes dropped 15 feet (4.6 m) or more and they are usually artificially cooled by the fire department. UL also runs an indirect explosion test on all safes. Additionally UL-768 certifies the combination lock against tampering. UL-140 certifies a relocking mechanism that will permanently lock the safe bolts, in case an electronic lock fails or a UL-768 rated lock is compromised.

Class 125

The container sustains an internal atmosphere of 125 °F (52 °C) and 80% humidity. This class was introduced with the emergence of floppy disks. The containers are tested with only non-paper media, but are clearly sufficient to hold paper. New, more durable computer media, such as data on compact disks crystallize at 350 °F (177 °C),[6] which make this type of safe overly-sufficient to store these media.

However, Underwriters Laboratories have not tested whether data on Blu-ray disks, DVDs or CDs are altered during testing. Only floppy disks were tested, which are no longer a common storage medium.[citation needed]

An added benefit of this container is that it is waterproof due to a door gasket, which is stated on the label. These class ratings are used in conjunction with hour ratings such as: ½, 1, 2, 3, or 4.[citation needed]

Class 150

The container sustains an internal atmosphere less than 150 °F (66 °C) and 85% humidity. This class was introduced with the emergence of computer data tapes or magnetic reel-to-reel tapes. UL tests this with paper and non-paper articles. This container is also sufficient in storing some optical media, such as compact disks. Cases can be purchased that will meet Class 125, if they are placed inside a Class 150 safe. Some may be waterproof due to a gasket on the door and the label will state this. These class ratings are used in conjunction with hour ratings such as: ½, 1, 2, 3, or 4.

Class 350

The container sustains an internal atmosphere of less than 350 °F (177 °C) and 85% humidity. This is the most basic of U.L. tests and specifically tests for the storage of paper. The autoignition temperature of paper is about 450 °F (232 °C), so this container is sufficient for storage of paper. Cases can be purchased that will meet Class 125, if they are placed inside a Class 350 container. These class ratings are used in conjunction with hour ratings such as: ½, 1, 2, 3, or 4.

Residential Security Container

Main article: Gun safe

While colloquially called "gun safes" in North America, residential security containers do not meet the same UL standards against burglary and tool resistance as described below. They have their own UL standard (UL 1037),[7] which is much less rigorous against attacks (having to withstand attacks for only five minutes), and are generally only to be used in non-commercial settings.[8]

Class TL-15

This is a combination locked safe that offers limited protection against combinations of common mechanical and electrical tools. The safe will resist abuse for 15 minutes from tools such as hand tools, picking tools, mechanical or electric tools, grinding points, carbide drills and devices that apply pressure. Anything with a TL-rating conforms to UL 687.[9]

Class TL-30

This is a combination locked safe that offers moderate protection against combinations of mechanical and electrical tools. The safe will resist abuse for 30 minutes from tools such as hand tools, picking tools, mechanical or electrical tools, grinding points, carbide drills, devices that apply pressure, cutting wheels and power saws.

Class TL-40

This is a combination locked safe that offers moderate protection against combinations of mechanical and electrical tools. The safe will resist abuse for 40 minutes from tools such as hand tools, picking tools, mechanical or electrical tools, grinding points, carbide drills, devices that apply pressure, cutting wheels and power saws.

Class TRTL-30

This is a combination locked safe that offers high protection against combinations of mechanical, electrical, and cutting tools. The safe will resist abuse for 30 minutes from tools such as hand tools, picking tools, mechanical or electrical tools, grinding points, carbide drills, devices that apply pressure, cutting wheels, power saws, impact tools and, in addition, can withstand an oxy-fuel welding and cutting torch (tested gas limited to 1,000 cubic feet (28 m3) combined total oxygen and fuel gas.)

Class TRTL-60

This class will withstand the same assaults as Class TRTL-30 for 60 minutes.

Class TXTL-60

This class meets all the requirements for Class TRTL-60 and, in addition, can withstand high explosives such as nitroglycerin or equivalent to not more than 4 ounces (110 g) of nitroglycerin in one charge (entire test must not use more explosive than that equivalent to 8 ounces (230 g) of nitroglycerin).

European Safe Standards

Depending on the usage, the European Committee for Standardization has published different European Standards for safes. Testing and certification according to these standards should be done by an accredited certification body, e.g. European Certification Body.[10]

EN 1143-1 is the main testing standard for safes, ATM safes, strongroom doors and strongrooms. For safes it features eleven resistance grades (0, I, II, …, to X). From one grade to the next the security rises by approximately 50%. Testing is based on a free choice of attack tools and methods. Testing requires partial access (hand hole) and complete access attempts, on all sides of the product. The security is calculated by using ratings of tools and the attack time. The result is expressed in resistance units (RU).[11]

EN 14450 is a testing standard for secure cabinets and strongboxes. The standard covers products meant for purposes where the security resistance required is less than that of EN 1143-1.[12]

For fire resistant safes the EN 1047-1 (fire resistance standard similar to the fire resistance safe standard of UL) and EN 15659 (for light fire storage units) were published.[13]

Gallery

Safe- iron with bronze decorations, including appliques heads of deities arranged in a row, found in Pompeii, now in the National Archaeological Museum of Naples

18th century sealable cashbox (Finnish customs service museum in Susisaari (fi), Suomenlinna

A hotel safe. It is secured to the wall, which makes it useful for protecting valuables against theft.

See also

Access control

Concealment device, an inconspicuous object used to hide things

Gun safe

Lock, a mechanical fastening device

Manual override, opening a safe without cracking it

Physical security

Safe-cracking, opening a safe without the combination

Safe deposit box, a lightweight safe

Security

Safe room

Strongroom, a bank vault

Time-delay combination locks

The Housatonic Railroad (/ˌhuːsəˈtɒnɪk/ HOOS-ə-TON-ik) (reporting mark HRRC) is a Class III railroad operating in southwestern New England. It was chartered in 1983 to operate a short section of ex-New York, New Haven and Hartford Railroad in northwestern Connecticut, and has since expanded north and south, as well as west into New York State.

The Housatonic Railroad was also a company chartered in 1836 and leased by the New Haven in 1892. It followed much the same route as the current company, but did not run west into New York.

History

Regional railroad: 1836-1898

Railroad tunnel which still exists, unused, in Newtown, Connecticut, as pictured in a postcard sent in 1905

The Housatonic Railroad, originally (mis)spelled as 'Ousatonic Railroad', was chartered in May 1836 to build a line from Bridgeport, Connecticut, north to the Massachusetts state line, along the Housatonic River valley. On February 19, 1840, regular service began from Bridgeport to New Milford, and on December 1, 1842, it opened to the state line.

On the other side of the line, the Berkshire Railroad was incorporated April 13, 1837, to continue the line north to West Stockbridge, where it would connect to the West Stockbridge Railroad (see below) and the never-built Lee and Hudson Railroad. Construction began in February 1841, and it was completed on December 1, 1842, the same day the line in Connecticut opened. The Housatonic Railroad leased the Berkshire Railroad on January 1, 1843.

The West Stockbridge Railroad was chartered in 1831 and incorporated April 5, 1836 to run from West Stockbridge west to State Line, where it would continue to the Hudson River in New York State as the Hudson and Berkshire Railroad. The line opened on August 10, 1838. On February 6, 1844, the Berkshire Railroad (then leased to the Housatonic) leased the West Stockbridge and Hudson and Berkshire Railroads. On November 21, 1854, the Western Railroad bought the Hudson and Berkshire, which became a branch from the Western's line (later the Boston and Albany Railroad) from Chatham to Hudson, and was abandoned east of Hudson. The West Stockbridge Railroad stayed part of the Housatonic system.

The final section of main line was incorporated March 20, 1847, as the Stockbridge and Pittsfield Railroad. This line split from the original main line at Van Deusenville in Great Barrington and ran east and north to Pittsfield. The full line opened on January 1, 1850, under operation of the Housatonic, and was formally leased January 25.

For a time the Housatonic operated the Pittsfield and North Adams Railroad, running north from the Western Railroad east of Pittsfield to North Adams, but it was returned to the Boston and Albany Railroad, the successor to the Western, in the early 1870s.

The Danbury and Norwalk Railroad opened in 1852 from Danbury south to Norwalk. The New York, Housatonic and Northern Railroad was chartered in 1863 to run from White Plains, New York, northeast via Danbury to Brookfield, Connecticut, on the Housatonic. It was only built north of Danbury, and on May 1, 1874, the Housatonic leased and opened it. On May 6, 1881, the Housatonic outright bought it, and on July 27, 1887, the Housatonic leased the Danbury and Norwalk, by then including branches to Ridgefield and Hawleyville (the latter on the Housatonic's main line) and a southern extension to Wilson Point.

Penn Central Railroad Form 110 effective February 1, 1971, showing the final schedule for train service on the former Housatonic Railroad between Danbury, Connecticut and Pittsfield, Massachusetts. At that time the service has been cut down to one train per week.

In the meantime, the New Haven and Derby Railroad was chartered in 1864 to run from New Haven west to Derby, Connecticut, and north to Ansonia, planned as part of the route over the never-built Hudson Highland Suspension Bridge. It opened in 1871. On November 14, 1888, a 3.79-mile (6.10 km) extension from Derby Junction to a point in Shelton was opened. The rest of the extension, 9.79 mi (15.76 km) from that point to the Housatonic Railroad at Botsford, was built by the Housatonic and opened on November 28. On July 9, 1889, the Housatonic leased the New Haven and Derby.

On July 1, 1892, the New York, New Haven and Hartford Railroad leased the Housatonic, forming the Berkshire Division; it was merged on March 29, 1898.

New Haven's Berkshire Division: 1892-1969

By the end of the New Haven's life, the Housatonic's original main line had been abandoned south of Botsford, where the old New Haven branch ran only east to Derby. The main line was also gone between Brookfield and Hawleyville, with traffic using the branch to Danbury and old New York and New England Railroad. The Danbury and Norwalk was still in use, but most branches, including the original main line to State Line, Massachusetts, were gone.

On January 1, 1969 the New Haven was merged into Penn Central, which named the lines as follows:

Pittsfield Branch: Berkshire Junction near Danbury north to Pittsfield

Maybrook Branch: Derby Junction west via Danbury and other New Haven lines to Campbell Hall, New York

Danbury Branch: Danbury and Norwalk Railroad

Penn Central and Conrail: 1969-1983

The last passenger train ran over the route on April 30, 1971, the day before Amtrak took over Penn Central's passenger operations. At that time, the travel time from Danbury to Pittsfield required two hours and 45 minutes. By 1974 the middle section was abandoned, between Boardman Bridge in New Milford and Canaan, Connecticut, and was not made part of Conrail on April 1, 1976, instead being bought by the State of Connecticut. In 1982 the Boston and Maine Railroad bought the line north of Canaan, renaming it the Canaan Running Track. Conrail continued to operate the line south of New Milford, and the old Danbury and Norwalk Railroad was conveyed to the Metro-North Commuter Railroad on January 1, 1983, becoming their Danbury Branch.

The New Housatonic Railroad (1983-Present)

Housatonic Railroad EMD GP35 #3604 at Canaan CT in 2004

A new Housatonic Railroad was chartered in 1983 by John Hanlon, Jr. to lease 34 miles of the former line, from Boardman Bridge in New Milford north to Canaan, Connecticut, from the State of Connecticut. Excursion trains began operating between Canaan and just south of Cornwall Bridge (at Belsprings Siding) in November 1984. The rest of the line, south into New Milford, was made serviceable in 1989, giving the company two connections - the Boston and Maine Railroad (Guilford Rail System) in Canaan and Conrail in New Milford. In April the Housatonic began to serve Becton, Dickinson and Company, a plastics plant in Canaan, but almost immediately the line was severed at Falls Village by a washout, not repaired until 14 months later.

Expansion into Massachusetts and New York

The Housatonic Transportation Company was incorporated in Delaware on January 2, 1991 as a holding company for the railroad's properties, including the newly formed Danbury Terminal Railroad (reporting mark DTRR) (an operating company) and Maybrook Properties (a land-owning company). That month the Housatonic bought the connecting Guilford trackage (Canaan Running Track) north to Pittsfield, Massachusetts, where it obtained another interchange with Conrail.

In December 1992 the Danbury Terminal Railroad acquired trackage and rights belonging to Conrail in southwestern Connecticut and southeastern New York. Maybrook Properties bought the former New Haven line (then the Danbury Secondary Track) from Beacon, New York (MP 0.0), east to Hopewell Junction (MP 12.8) (former Newburg, Dutchess and Connecticut Railroad), Hopewell Junction (MP 42.9) east to Derby, Connecticut (MP 104.8), (former Hartford, Providence and Fishkill Railroad, Housatonic Railroad and branch to Derby). The Danbury Terminal operated this Maybrook Properties-owned trackage. The Danbury Terminal also obtained Conrail's former trackage rights to serve freight on the Metro-North Commuter Railroad's Harlem Line from White Plains (MP 22.0) to Dover Plains (MP 76.6), and north to Wassaic (MP 81.6) over trackage still owned by the New York and Harlem Railroad and leased to Conrail, crossing the east-west line at Dykemans. Finally, it obtained overhead trackage rights over Metro-North's Waterbury Branch from the east end of this line at Derby (MP 8.9) south to Devon, Connecticut (MP 0.0), (operated for freight by the Providence and Worcester Railroad). The Housatonic also acquired the final part of the main line, from New Milford south to the east-west line at Berkshire Junction near Danbury. With this acquisition, the Housatonic gained a much expanded system and several new customers. These new acquisitions were first operated January 2, 1993.

While freight customers remained on Metro-North's Harlem Line, the HRRC was not allowed to serve them directly. A few freight shipments were forwarded from Danbury by Metro-North crews, but this arrangement was only temporary until the remaining customers converted to truck transportation. On December 31, 1996, the Danbury Terminal Railroad was merged into the Housatonic Railroad.

In 1984, the Berkshire Scenic Railway Museum began operating passenger excursions between Lee and Great Barrington, over tracks owned by the Housatonic Railroad. Due to deteriorating track conditions, passenger operations were suspended in 1989. The museum successfully campaigned for state assistance funds to upgrade the tracks. The excursion trains returned in 2003, based out of the restored station in Lenox, with regular schedules to Lee and Stockbridge.

Excursions End, Freight Shipments Decline

In 2008 HRRC considering the possibility of resuming commercial passenger service along the entire line from Danbury to Pittsfield, and in May 2010 began a formal study of the same. The estimated cost of upgrading the railroad to support passenger trains was estimated to be between 0 million and 0 million, not including the cost of the required equipment.[1]

In 2011, the Housatonic Railroad decided it would not renew its agreement with BSRM to continue operating passenger excursions over their railroad. Colin Pease, spokesperson for HRRC, said, "The Housatonic Railroad has determined that the continued operation of the Berkshire Scenic Railway on Housatonic-owned tracks is no longer possible." Despite millions invested by the state, track conditions grew worse and freight shipments declined.

In July 2014, Massachusetts Department of Transportation's Board of Directors authorized the purchase of 37 miles of the railroad's Berkshire Line. MassDOT's purchase is intended to extend rail services to New York City, following track improvements for passenger and freight service between Massachusetts and Connecticut.[2][3]

See also

Railways portal

List of New York, New Haven and Hartford Railroad precursors